Anion Resin Filter Cartridge (Refillable) for Tannin Reduction, Size - 10" x 2.5"

Anion Resin Filter Cartridge (Refillable) for Tannin Reduction, Size - 10" x 2.5" - 1 Pack is backordered and will ship as soon as it is back in stock.

Description

Description

Our Tannin Anion Filter employs advanced acrylic-based and high water retention/low crosslinked styrene-based resins for superior tannin removal in residential water treatment. Designed to outperform traditional ion exchange resins, this filter effectively addresses issues related to tannins and organic compounds that can cause water discoloration and affect taste and odor. With proven success in pilot studies, this innovative solution offers enhanced efficiency in treating tannins, ensuring clear and appealing water quality. The filter demands proper storage care, with a recommended temperature range of 20°C to 40°C, and precautions are advised when handling corrosive solutions during the regeneration process. Upgrade your water treatment with our advanced Tannin Anion Filter for a reliable and efficient solution.

Shipping & Returns

Shipping & Returns

Shipping

We currently ship to the United States and Canada. To enquire about shipping to a different destination, please contact us.

Standard shipping normally takes 3-9 days. Next-day shipping is available on all domestic orders (for an additional charge). International shipping times depend on the products and destination (estimated at checkout).

Returns

Items must be returned within 30 days after receiving your order. Items must be returned in the same condition in which they were received, be unworn/unused, have any tags still attached, and include all the original packaging.

Please be aware that the seller will not cover the cost of the return label. It is the customer's responsibility to generate the return shipping label and send the system back to our warehouse.

Refunds

Refunds are processed within 7 days from when we receive the item(s).

Join and get free shipping on orders over $100

First-time purchasers will receive a special discount code sent to their email.

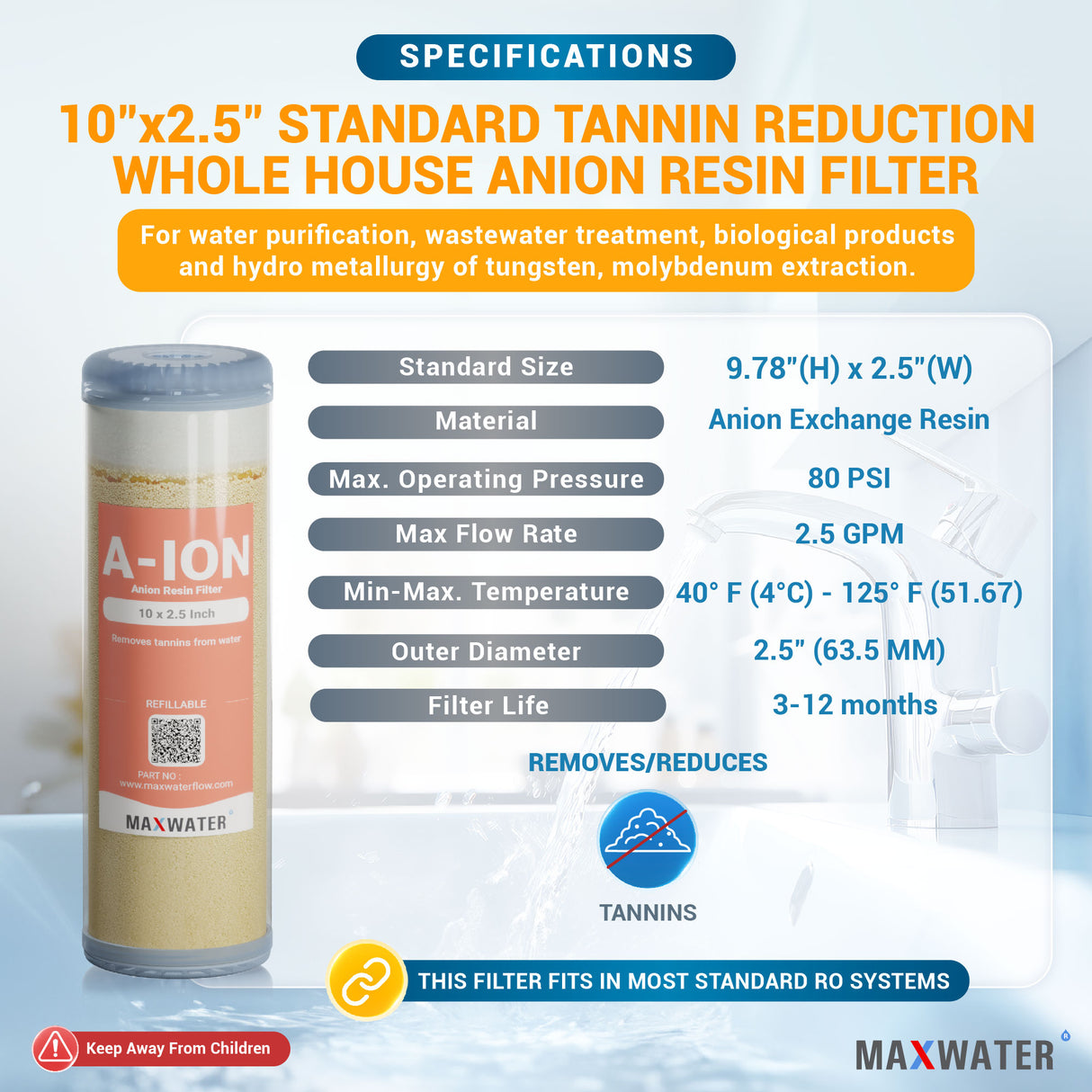

10-inch x 2.5-Inch Standard Anion Resin Filter Cartridge for Tannins Reduction(refillable)

Our 10-inch Standard Anion Resin Filter is designed to effectively reduce and eliminate tannins from incoming water. Particularly beneficial for well water or water sources exhibiting persistent brownish discoloration, resistant to sediment or Iron/Manganese filters, this anion filter provides a potential solution.

Tannins, known for their astringent and bitter taste, are plant polyphenols that bind and precipitate proteins. In the context of water treatment, the term refers to the brown discoloration caused by decaying organic matter, often present in well waters due to the formation of tannins from humic acid. This acid, a complex mixture resulting from the biodegradation of organic matter, contains carboxyl and phenolate groups.

The 10" Anion Resin Filter is formulated to address water with a pH above 6, where tannins tend to form anions. However, for water with a pH below 5, activated carbon is recommended for more effective treatment.

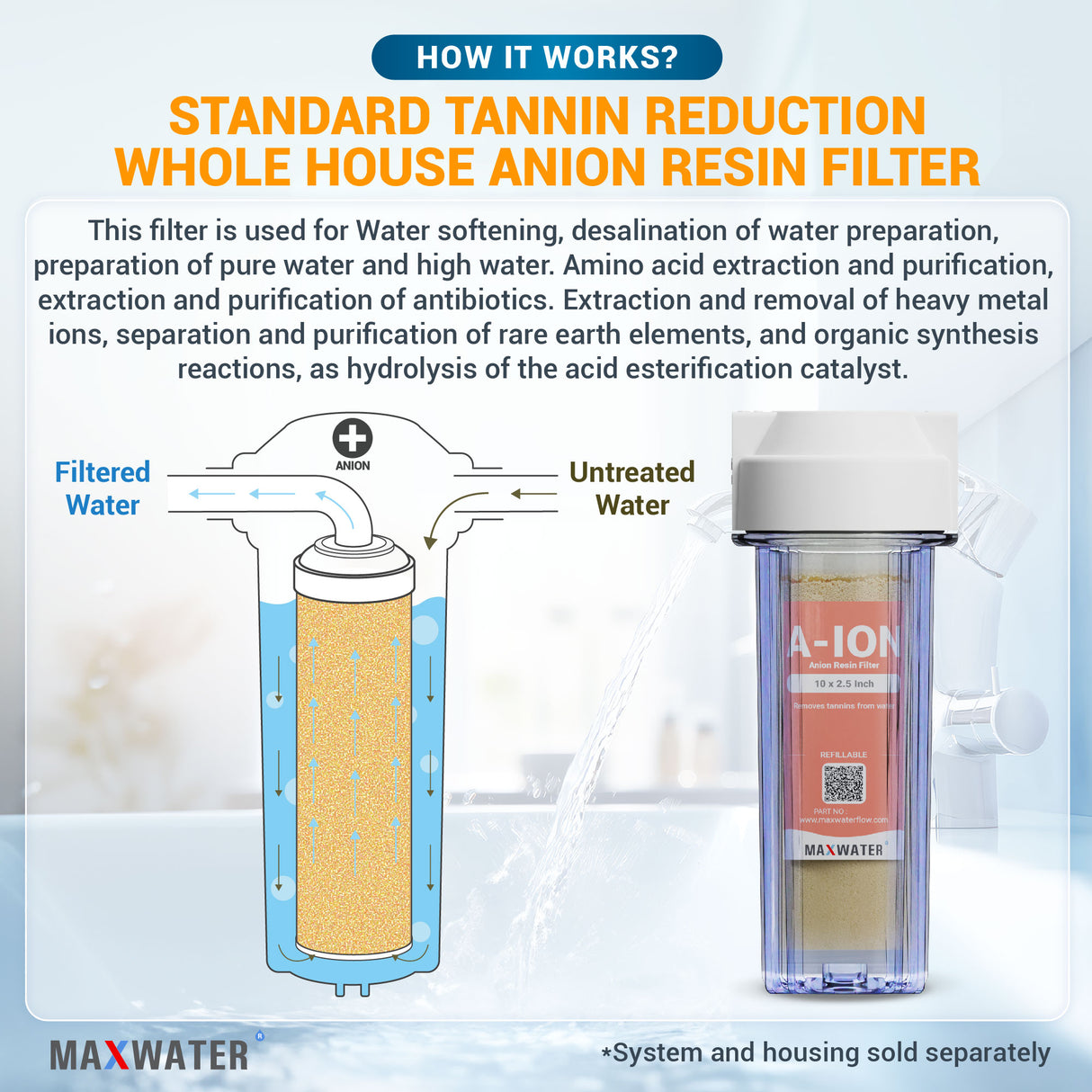

This exchange anion is suitable for various applications, including de-ionization in water filtration systems, chemical processing, and scientific processes like ultra-pure water production, organic substance separation, antibiotic medicine refinement, and biochemical product separation and extraction.

Primary Uses:

- Water purification

- Wastewater treatment

- Biological product processing

- Hydrometallurgy of tungsten

- Molybdenum extraction

Other Applications:

- Water softening

- Desalination of water preparation

- Preparation of pure water and high water

- Amino acid extraction and purification

- Extraction and purification of antibiotics

- Extraction and removal of heavy metal ions

- Separation and purification of rare earth elements

- Organic synthesis reactions, acting as a hydrolysis and acid esterification catalyst.

Tannin Removal

- Addressing tannin removal has posed a challenge for some dealers, with standard strong base macroporous anion resins, crafted from styrene and divinylbenzene, traditionally employed until several years ago. Although effective in certain regions, this resin type encountered limitations in others. Over the past five to ten years, the residential water market has witnessed the introduction of more successful resins, making the tannin removal application more appealing to water treatment dealers.

- Softening the water before the tannin removal unit is often recommended. This step ensures the elimination of hardness and metals like iron, which could potentially compromise the performance of the anion resin. Tannins, however, can pass through softening (cation) resin without adverse effects. When hardness levels exceed 10 grains entering the tannin removal unit, there's a risk of precipitating calcium carbonate, forming a white floc that may impede system flow and obstruct exchange sites on the resin. Additionally, metals like iron can foul the anion resin, diminishing its ability to remove tannins. Methods for cleaning these foulants will be discussed later.

- Tannins, large molecular-weight organic compounds resulting from plant and animal decomposition, primarily exist in surface waters or shallow wells. Two main categories of tannins are Humic acid and Fulvic acid, each exhibiting varying structures depending on the vegetation in a given area. Tannins can impart a yellow to dark tea color to water, affecting taste and odor. While not directly regulated, a secondary drinking water standard of 15 alpha units for color exists, although it is not federally enforced. Although not posing health concerns, tannins are aesthetically displeasing.

- Dealing with tannins in water can be challenging, with treatment methods varying in effectiveness based on location and vegetation. While styrene-based macroporous anion resin has traditionally been used for tannin removal, acrylic-based resins have recently emerged, providing excellent results in most cases. These resins can be manufactured as gels or with macroporosity, and low crosslinked/high water retention styrene-based resins have also proven successful in some applications.

| Property | Specification |

|---|---|

| Applications | Removal of organics and color from water |

| Resin Type | Macroporous Strong Base Anion |

| Matrix Type | Styrene divinylbenzene copolymer |

| Functional Groups | Quaternary ammonium |

| Ionic form as supplied | Chloride |

| Total exchange capacity | 0.95 meq/ml, minimum |

| Moisture holding capacity | 57 - 66 % |

| Uniformity co-efficient | 0.45 to 0.55 mm |

| Effective size | 0.8 |

| Maximum operating temperature | 125℉ |

| Operating pH range | 4 to 10 for organic removal |

| Resistance to reducing agents | Good |

| Resistance to oxidizing agents | Generally good, chlorine should be absent |

| Particle size range : 0.3 to 1.2 mm > 1.2 mm <0.3 mm |

0.3 to 1.2 mm 5.0%, maximum 1.0%, maximum |

If your well water exhibits a slight yellow or brown tint, adding one pound per inch in diameter to your media tank typically restores clarity to the water. For darker water resembling iced tea, you may require up to two pounds per inch in diameter of your media tank.

Although there's mention of using a separate tank solely for tannin removal, our approach involves directly introducing these beads into the existing tank, on top of the regular ones in the water softener, without removing any beads.

To assess the "color" or "tannins," run the water at the well for a brief period, then promptly take a sample in a white cup, bucket, or clear glass. Observe the color immediately before the iron has a chance to react with the air (oxygen). Only if color is present when water is initially drawn would the additional tannin removal resin be deemed necessary alongside your regular softening resins.

Application - Organics; Tannin Removal and Demineralization - Demonstrates excellent resistance to fouling.

Here is some general information on estimating the approximate level of tannins in your water.

| Concentration in parts-per Million (PPM) | Water Color |

|---|---|

| 0.0 - 0.5 | Faint tinge of yellow |

| 0.5 - 2.0 | Darker golden yellow |

| 2.0 - 3.0 | Light team color |

| 3.0 - 5.0 | Dark tea color |

Service Cycle Overview:

- The process of tannin removal using anion exchange resins involves a dual mechanism of ion exchange and absorption. Tannins, possessing a slightly negative charge, are exchanged for chloride ions on the resin. Additionally, it is believed that the anion resin can absorb organic compounds. Regeneration of the anion resin is achieved using salt, typically brined at around 10 lbs per cubic foot of salt (NaCl). Regular regeneration is crucial to maintaining resin efficacy.

- Once tannins are exchanged or absorbed onto the resin, they tend to migrate into the inner matrix of the resin bead. Timely regeneration, ideally every two to three days, is essential. Frequent regenerations decrease the likelihood of organic fouling, while extended intervals promote fouling, regardless of whether the anion resin is acrylic or styrene-based.

- The incorporation of tannin resin with softening resin is a common practice, optimizing equipment space and reducing system costs. However, during regeneration, salt may displace calcium from the cation resin and potentially alkalinity from the anion/tannin resin, leading to calcium carbonate precipitation. Indicators of precipitation include a white precipitate in the resin bed, a coating on the drain line, a pressure drop through the system, or a milky-white substance in the backwash water. Cleaning methods will be discussed later.

- Anion resin, with lower density compared to cation resin, requires a distinct backwash flow rate. While the backwash flow rate for cation-softening resin is approximately five gpm/square foot (sf) of area, the anion should be backwashed at around two gpm/sf. In dual bed systems combining softening and tannin removal resins, backwash adjustments or the use of an upper screen or basket in the valve prevent resin loss.

- Tannin resin is often associated with a fishy odor, attributed to the release of an amine by-product from the anion resin. Although the amine concentrations are generally low, the odor threshold is around 40 parts per billion, causing aesthetic displeasure. The fishy odor is more prevalent when water is chlorinated and has a high pH (>8), often occurring with the use of chloramines as a disinfectant. It is advisable to remove any oxidant (chlorine, chloramine, or peroxide) before the anion unit.

- As water passes through a chloride-form anion resin, alkalinity is removed, leading to a decrease in pH. The anion resin has a limited capacity for alkalinity, causing a brief pH decrease during the service cycle. The treated water's chloride content increases, and it is essential to check local water treatment regulations for any chloride limits. Chlorides have a secondary drinking water standard of 250 ppm. If influent water TDS levels exceed 800 ppm, a salty taste may be detected in the treated water, necessitating the use of reverse osmosis (RO) to reduce TDS and eliminate the salty taste.

Methods of Cleaning:

- To address calcium carbonate precipitation, a weak acid such as citric or phosphoric acid proves effective. Compatibility with the unit and associated plumbing is essential when selecting a cleaning agent, and this method is generally suitable for treating various types of metal fouling.

- When tannin color passes through a previously functioning unit, an attempt to clean the resin is warranted. For this, soda ash (Na2CO3) can be introduced into the brine to aid in cleaning the anion resin. Typically, 0.5 to 1 pound of soda ash is added to the brine well. The soda ash elevates the pH of the brine, causing the resin to swell further, enlarging the pores for enhanced elution of tannins. Additionally, tannins are more soluble at higher pH levels, creating an environment conducive to stripping them from the resin. Note that this cleaning process may result in the fishy odor. After treating the resin with soda ash, a second regeneration should be conducted to completely convert the resin to the chloride form.

- If soda ash proves ineffective in cleaning the resin, chlorine treatment can be employed as a last resort. Introduce approximately four to eight ounces of standard household bleach into the brine well and initiate the regeneration process. Once a chlorine odor is discernible in the drain line, pause the system for one to two hours, and resume the remainder of the regeneration cycle after the soak. A second regeneration is necessary to eliminate any residual chlorine. It's crucial to recognize that this cleaning procedure is harsh on the resin and should be considered a final option. Oxidants like chlorine can break down ion exchange resin, and although there is no resin on the market that is entirely chlorine-resistant, some are more chlorine-tolerant. The tannin resins in today's water treatment market are relatively chlorine-intolerant. If this treatment proves unsuccessful, replacement should be contemplated.

- If the unit houses both cation and anion, it is advisable to regenerate the bed with salt before attempting any cleaning procedure. Metals, such as iron, may precipitate on the cation resin due to high pH or oxidation.

Alternative Approaches to Tannin Removal:

- Oxidizing agents, such as chlorine, prove effective in breaking down organic compounds like tannins. A simple jar test can reveal the concentration and retention time needed to oxidize tannins. Following the retention tank, an activated carbon unit can eliminate chlorine and potentially adsorb other organic compounds in the water. Certain types of activated carbon alone may also reduce tannin levels to acceptable thresholds. It is crucial to consult with your carbon manufacturer to identify the most suitable product. It's worth noting that the reaction between chlorine and tannins may generate trihalomethanes (THMs), recognized carcinogens.

- Reverse osmosis represents another viable method for tannin removal. Given that tannins are high molecular weight organics, reverse osmosis should effectively reject them. However, tannins may pose a challenge by fouling the membrane in the system. Additionally, installing a whole-house reverse osmosis system to treat all water can be prohibitively expensive. For detailed information, it is recommended to consult with your local water expert.

Conclusion:

- Historically, tannin removal predominantly relied on carbon- and styrene-based ion exchange resins. However, recent advancements in water treatment have introduced acrylic-based and high water retention/low crosslinked styrene-based anion exchange resins to the residential market, demonstrating superior performance in tannin removal compared to traditional ion exchange resins. While no resin achieves 100 percent effectiveness, these newer resins have significantly enhanced success rates. If you haven't attempted tannin treatment recently, it might be worth exploring again. For any new water treatment application or product, conduct pilot testing with several systems in the field. Once the pilot study validates the effectiveness in a specific area, pursue the business.

Storage:

- Proper care is essential for ion exchange resins throughout their storage. Prevent the resins from drying out by regularly inspecting their condition when stored in plastic bags. If the resin is not moist, add sufficient clean demineralized water to maintain a consistently moist state. Store the resin drum in a shaded area, and the recommended storage temperature falls between 20°C and 40°C.

Safety:

- Exercise caution with acid and alkali solutions used for regeneration, as they are corrosive and should be handled to prevent eye and skin contact. When utilizing oxidizing agents, adhere to necessary safety precautions to prevent accidents and potential damage to the resin.

10-inch x 2.5-Inch Standard Anion Resin Filter Cartridge for Tannins Reduction(refillable)

Our 10-inch Standard Anion Resin Filter is designed to effectively reduce and eliminate tannins from incoming water. Particularly beneficial for well water or water sources exhibiting persistent brownish discoloration, resistant to sediment or Iron/Manganese filters, this anion filter provides a potential solution.

Tannins, known for their astringent and bitter taste, are plant polyphenols that bind and precipitate proteins. In the context of water treatment, the term refers to the brown discoloration caused by decaying organic matter, often present in well waters due to the formation of tannins from humic acid. This acid, a complex mixture resulting from the biodegradation of organic matter, contains carboxyl and phenolate groups.

The 10" Anion Resin Filter is formulated to address water with a pH above 6, where tannins tend to form anions. However, for water with a pH below 5, activated carbon is recommended for more effective treatment.

This exchange anion is suitable for various applications, including de-ionization in water filtration systems, chemical processing, and scientific processes like ultra-pure water production, organic substance separation, antibiotic medicine refinement, and biochemical product separation and extraction.

Primary Uses:

- Water purification

- Wastewater treatment

- Biological product processing

- Hydrometallurgy of tungsten

- Molybdenum extraction

Other Applications:

- Water softening

- Desalination of water preparation

- Preparation of pure water and high water

- Amino acid extraction and purification

- Extraction and purification of antibiotics

- Extraction and removal of heavy metal ions

- Separation and purification of rare earth elements

- Organic synthesis reactions, acting as a hydrolysis and acid esterification catalyst.

Tannin Removal

- Addressing tannin removal has posed a challenge for some dealers, with standard strong base macroporous anion resins, crafted from styrene and divinylbenzene, traditionally employed until several years ago. Although effective in certain regions, this resin type encountered limitations in others. Over the past five to ten years, the residential water market has witnessed the introduction of more successful resins, making the tannin removal application more appealing to water treatment dealers.

- Softening the water before the tannin removal unit is often recommended. This step ensures the elimination of hardness and metals like iron, which could potentially compromise the performance of the anion resin. Tannins, however, can pass through softening (cation) resin without adverse effects. When hardness levels exceed 10 grains entering the tannin removal unit, there's a risk of precipitating calcium carbonate, forming a white floc that may impede system flow and obstruct exchange sites on the resin. Additionally, metals like iron can foul the anion resin, diminishing its ability to remove tannins. Methods for cleaning these foulants will be discussed later.

- Tannins, large molecular-weight organic compounds resulting from plant and animal decomposition, primarily exist in surface waters or shallow wells. Two main categories of tannins are Humic acid and Fulvic acid, each exhibiting varying structures depending on the vegetation in a given area. Tannins can impart a yellow to dark tea color to water, affecting taste and odor. While not directly regulated, a secondary drinking water standard of 15 alpha units for color exists, although it is not federally enforced. Although not posing health concerns, tannins are aesthetically displeasing.

- Dealing with tannins in water can be challenging, with treatment methods varying in effectiveness based on location and vegetation. While styrene-based macroporous anion resin has traditionally been used for tannin removal, acrylic-based resins have recently emerged, providing excellent results in most cases. These resins can be manufactured as gels or with macroporosity, and low crosslinked/high water retention styrene-based resins have also proven successful in some applications.

| Property | Specification |

|---|---|

| Applications | Removal of organics and color from water |

| Resin Type | Macroporous Strong Base Anion |

| Matrix Type | Styrene divinylbenzene copolymer |

| Functional Groups | Quaternary ammonium |

| Ionic form as supplied | Chloride |

| Total exchange capacity | 0.95 meq/ml, minimum |

| Moisture holding capacity | 57 - 66 % |

| Uniformity co-efficient | 0.45 to 0.55 mm |

| Effective size | 0.8 |

| Maximum operating temperature | 125℉ |

| Operating pH range | 4 to 10 for organic removal |

| Resistance to reducing agents | Good |

| Resistance to oxidizing agents | Generally good, chlorine should be absent |

| Particle size range : 0.3 to 1.2 mm > 1.2 mm <0.3 mm |

0.3 to 1.2 mm 5.0%, maximum 1.0%, maximum |

If your well water exhibits a slight yellow or brown tint, adding one pound per inch in diameter to your media tank typically restores clarity to the water. For darker water resembling iced tea, you may require up to two pounds per inch in diameter of your media tank.

Although there's mention of using a separate tank solely for tannin removal, our approach involves directly introducing these beads into the existing tank, on top of the regular ones in the water softener, without removing any beads.

To assess the "color" or "tannins," run the water at the well for a brief period, then promptly take a sample in a white cup, bucket, or clear glass. Observe the color immediately before the iron has a chance to react with the air (oxygen). Only if color is present when water is initially drawn would the additional tannin removal resin be deemed necessary alongside your regular softening resins.

Application - Organics; Tannin Removal and Demineralization - Demonstrates excellent resistance to fouling.

Here is some general information on estimating the approximate level of tannins in your water.

| Concentration in parts-per Million (PPM) | Water Color |

|---|---|

| 0.0 - 0.5 | Faint tinge of yellow |

| 0.5 - 2.0 | Darker golden yellow |

| 2.0 - 3.0 | Light team color |

| 3.0 - 5.0 | Dark tea color |

Service Cycle Overview:

- The process of tannin removal using anion exchange resins involves a dual mechanism of ion exchange and absorption. Tannins, possessing a slightly negative charge, are exchanged for chloride ions on the resin. Additionally, it is believed that the anion resin can absorb organic compounds. Regeneration of the anion resin is achieved using salt, typically brined at around 10 lbs per cubic foot of salt (NaCl). Regular regeneration is crucial to maintaining resin efficacy.

- Once tannins are exchanged or absorbed onto the resin, they tend to migrate into the inner matrix of the resin bead. Timely regeneration, ideally every two to three days, is essential. Frequent regenerations decrease the likelihood of organic fouling, while extended intervals promote fouling, regardless of whether the anion resin is acrylic or styrene-based.

- The incorporation of tannin resin with softening resin is a common practice, optimizing equipment space and reducing system costs. However, during regeneration, salt may displace calcium from the cation resin and potentially alkalinity from the anion/tannin resin, leading to calcium carbonate precipitation. Indicators of precipitation include a white precipitate in the resin bed, a coating on the drain line, a pressure drop through the system, or a milky-white substance in the backwash water. Cleaning methods will be discussed later.

- Anion resin, with lower density compared to cation resin, requires a distinct backwash flow rate. While the backwash flow rate for cation-softening resin is approximately five gpm/square foot (sf) of area, the anion should be backwashed at around two gpm/sf. In dual bed systems combining softening and tannin removal resins, backwash adjustments or the use of an upper screen or basket in the valve prevent resin loss.

- Tannin resin is often associated with a fishy odor, attributed to the release of an amine by-product from the anion resin. Although the amine concentrations are generally low, the odor threshold is around 40 parts per billion, causing aesthetic displeasure. The fishy odor is more prevalent when water is chlorinated and has a high pH (>8), often occurring with the use of chloramines as a disinfectant. It is advisable to remove any oxidant (chlorine, chloramine, or peroxide) before the anion unit.

- As water passes through a chloride-form anion resin, alkalinity is removed, leading to a decrease in pH. The anion resin has a limited capacity for alkalinity, causing a brief pH decrease during the service cycle. The treated water's chloride content increases, and it is essential to check local water treatment regulations for any chloride limits. Chlorides have a secondary drinking water standard of 250 ppm. If influent water TDS levels exceed 800 ppm, a salty taste may be detected in the treated water, necessitating the use of reverse osmosis (RO) to reduce TDS and eliminate the salty taste.

Methods of Cleaning:

- To address calcium carbonate precipitation, a weak acid such as citric or phosphoric acid proves effective. Compatibility with the unit and associated plumbing is essential when selecting a cleaning agent, and this method is generally suitable for treating various types of metal fouling.

- When tannin color passes through a previously functioning unit, an attempt to clean the resin is warranted. For this, soda ash (Na2CO3) can be introduced into the brine to aid in cleaning the anion resin. Typically, 0.5 to 1 pound of soda ash is added to the brine well. The soda ash elevates the pH of the brine, causing the resin to swell further, enlarging the pores for enhanced elution of tannins. Additionally, tannins are more soluble at higher pH levels, creating an environment conducive to stripping them from the resin. Note that this cleaning process may result in the fishy odor. After treating the resin with soda ash, a second regeneration should be conducted to completely convert the resin to the chloride form.

- If soda ash proves ineffective in cleaning the resin, chlorine treatment can be employed as a last resort. Introduce approximately four to eight ounces of standard household bleach into the brine well and initiate the regeneration process. Once a chlorine odor is discernible in the drain line, pause the system for one to two hours, and resume the remainder of the regeneration cycle after the soak. A second regeneration is necessary to eliminate any residual chlorine. It's crucial to recognize that this cleaning procedure is harsh on the resin and should be considered a final option. Oxidants like chlorine can break down ion exchange resin, and although there is no resin on the market that is entirely chlorine-resistant, some are more chlorine-tolerant. The tannin resins in today's water treatment market are relatively chlorine-intolerant. If this treatment proves unsuccessful, replacement should be contemplated.

- If the unit houses both cation and anion, it is advisable to regenerate the bed with salt before attempting any cleaning procedure. Metals, such as iron, may precipitate on the cation resin due to high pH or oxidation.

Alternative Approaches to Tannin Removal:

- Oxidizing agents, such as chlorine, prove effective in breaking down organic compounds like tannins. A simple jar test can reveal the concentration and retention time needed to oxidize tannins. Following the retention tank, an activated carbon unit can eliminate chlorine and potentially adsorb other organic compounds in the water. Certain types of activated carbon alone may also reduce tannin levels to acceptable thresholds. It is crucial to consult with your carbon manufacturer to identify the most suitable product. It's worth noting that the reaction between chlorine and tannins may generate trihalomethanes (THMs), recognized carcinogens.

- Reverse osmosis represents another viable method for tannin removal. Given that tannins are high molecular weight organics, reverse osmosis should effectively reject them. However, tannins may pose a challenge by fouling the membrane in the system. Additionally, installing a whole-house reverse osmosis system to treat all water can be prohibitively expensive. For detailed information, it is recommended to consult with your local water expert.

Conclusion:

- Historically, tannin removal predominantly relied on carbon- and styrene-based ion exchange resins. However, recent advancements in water treatment have introduced acrylic-based and high water retention/low crosslinked styrene-based anion exchange resins to the residential market, demonstrating superior performance in tannin removal compared to traditional ion exchange resins. While no resin achieves 100 percent effectiveness, these newer resins have significantly enhanced success rates. If you haven't attempted tannin treatment recently, it might be worth exploring again. For any new water treatment application or product, conduct pilot testing with several systems in the field. Once the pilot study validates the effectiveness in a specific area, pursue the business.

Storage:

- Proper care is essential for ion exchange resins throughout their storage. Prevent the resins from drying out by regularly inspecting their condition when stored in plastic bags. If the resin is not moist, add sufficient clean demineralized water to maintain a consistently moist state. Store the resin drum in a shaded area, and the recommended storage temperature falls between 20°C and 40°C.

Safety:

- Exercise caution with acid and alkali solutions used for regeneration, as they are corrosive and should be handled to prevent eye and skin contact. When utilizing oxidizing agents, adhere to necessary safety precautions to prevent accidents and potential damage to the resin.

10-inch x 2.5-Inch Standard Anion Resin Filter Cartridge for Tannins Reduction(refillable)

Our 10-inch Standard Anion Resin Filter is designed to effectively reduce and eliminate tannins from incoming water. Particularly beneficial for well water or water sources exhibiting persistent brownish discoloration, resistant to sediment or Iron/Manganese filters, this anion filter provides a potential solution.

Tannins, known for their astringent and bitter taste, are plant polyphenols that bind and precipitate proteins. In the context of water treatment, the term refers to the brown discoloration caused by decaying organic matter, often present in well waters due to the formation of tannins from humic acid. This acid, a complex mixture resulting from the biodegradation of organic matter, contains carboxyl and phenolate groups.

The 10" Anion Resin Filter is formulated to address water with a pH above 6, where tannins tend to form anions. However, for water with a pH below 5, activated carbon is recommended for more effective treatment.

This exchange anion is suitable for various applications, including de-ionization in water filtration systems, chemical processing, and scientific processes like ultra-pure water production, organic substance separation, antibiotic medicine refinement, and biochemical product separation and extraction.

Primary Uses:

- Water purification

- Wastewater treatment

- Biological product processing

- Hydrometallurgy of tungsten

- Molybdenum extraction

Other Applications:

- Water softening

- Desalination of water preparation

- Preparation of pure water and high water

- Amino acid extraction and purification

- Extraction and purification of antibiotics

- Extraction and removal of heavy metal ions

- Separation and purification of rare earth elements

- Organic synthesis reactions, acting as a hydrolysis and acid esterification catalyst.

Tannin Removal

- Addressing tannin removal has posed a challenge for some dealers, with standard strong base macroporous anion resins, crafted from styrene and divinylbenzene, traditionally employed until several years ago. Although effective in certain regions, this resin type encountered limitations in others. Over the past five to ten years, the residential water market has witnessed the introduction of more successful resins, making the tannin removal application more appealing to water treatment dealers.

- Softening the water before the tannin removal unit is often recommended. This step ensures the elimination of hardness and metals like iron, which could potentially compromise the performance of the anion resin. Tannins, however, can pass through softening (cation) resin without adverse effects. When hardness levels exceed 10 grains entering the tannin removal unit, there's a risk of precipitating calcium carbonate, forming a white floc that may impede system flow and obstruct exchange sites on the resin. Additionally, metals like iron can foul the anion resin, diminishing its ability to remove tannins. Methods for cleaning these foulants will be discussed later.

- Tannins, large molecular-weight organic compounds resulting from plant and animal decomposition, primarily exist in surface waters or shallow wells. Two main categories of tannins are Humic acid and Fulvic acid, each exhibiting varying structures depending on the vegetation in a given area. Tannins can impart a yellow to dark tea color to water, affecting taste and odor. While not directly regulated, a secondary drinking water standard of 15 alpha units for color exists, although it is not federally enforced. Although not posing health concerns, tannins are aesthetically displeasing.

- Dealing with tannins in water can be challenging, with treatment methods varying in effectiveness based on location and vegetation. While styrene-based macroporous anion resin has traditionally been used for tannin removal, acrylic-based resins have recently emerged, providing excellent results in most cases. These resins can be manufactured as gels or with macroporosity, and low crosslinked/high water retention styrene-based resins have also proven successful in some applications.

| Property | Specification |

|---|---|

| Applications | Removal of organics and color from water |

| Resin Type | Macroporous Strong Base Anion |

| Matrix Type | Styrene divinylbenzene copolymer |

| Functional Groups | Quaternary ammonium |

| Ionic form as supplied | Chloride |

| Total exchange capacity | 0.95 meq/ml, minimum |

| Moisture holding capacity | 57 - 66 % |

| Uniformity co-efficient | 0.45 to 0.55 mm |

| Effective size | 0.8 |

| Maximum operating temperature | 125℉ |

| Operating pH range | 4 to 10 for organic removal |

| Resistance to reducing agents | Good |

| Resistance to oxidizing agents | Generally good, chlorine should be absent |

| Particle size range : 0.3 to 1.2 mm > 1.2 mm <0.3 mm |

0.3 to 1.2 mm 5.0%, maximum 1.0%, maximum |

If your well water exhibits a slight yellow or brown tint, adding one pound per inch in diameter to your media tank typically restores clarity to the water. For darker water resembling iced tea, you may require up to two pounds per inch in diameter of your media tank.

Although there's mention of using a separate tank solely for tannin removal, our approach involves directly introducing these beads into the existing tank, on top of the regular ones in the water softener, without removing any beads.

To assess the "color" or "tannins," run the water at the well for a brief period, then promptly take a sample in a white cup, bucket, or clear glass. Observe the color immediately before the iron has a chance to react with the air (oxygen). Only if color is present when water is initially drawn would the additional tannin removal resin be deemed necessary alongside your regular softening resins.

Application - Organics; Tannin Removal and Demineralization - Demonstrates excellent resistance to fouling.

Here is some general information on estimating the approximate level of tannins in your water.

| Concentration in parts-per Million (PPM) | Water Color |

|---|---|

| 0.0 - 0.5 | Faint tinge of yellow |

| 0.5 - 2.0 | Darker golden yellow |

| 2.0 - 3.0 | Light team color |

| 3.0 - 5.0 | Dark tea color |

Service Cycle Overview:

- The process of tannin removal using anion exchange resins involves a dual mechanism of ion exchange and absorption. Tannins, possessing a slightly negative charge, are exchanged for chloride ions on the resin. Additionally, it is believed that the anion resin can absorb organic compounds. Regeneration of the anion resin is achieved using salt, typically brined at around 10 lbs per cubic foot of salt (NaCl). Regular regeneration is crucial to maintaining resin efficacy.

- Once tannins are exchanged or absorbed onto the resin, they tend to migrate into the inner matrix of the resin bead. Timely regeneration, ideally every two to three days, is essential. Frequent regenerations decrease the likelihood of organic fouling, while extended intervals promote fouling, regardless of whether the anion resin is acrylic or styrene-based.

- The incorporation of tannin resin with softening resin is a common practice, optimizing equipment space and reducing system costs. However, during regeneration, salt may displace calcium from the cation resin and potentially alkalinity from the anion/tannin resin, leading to calcium carbonate precipitation. Indicators of precipitation include a white precipitate in the resin bed, a coating on the drain line, a pressure drop through the system, or a milky-white substance in the backwash water. Cleaning methods will be discussed later.

- Anion resin, with lower density compared to cation resin, requires a distinct backwash flow rate. While the backwash flow rate for cation-softening resin is approximately five gpm/square foot (sf) of area, the anion should be backwashed at around two gpm/sf. In dual bed systems combining softening and tannin removal resins, backwash adjustments or the use of an upper screen or basket in the valve prevent resin loss.

- Tannin resin is often associated with a fishy odor, attributed to the release of an amine by-product from the anion resin. Although the amine concentrations are generally low, the odor threshold is around 40 parts per billion, causing aesthetic displeasure. The fishy odor is more prevalent when water is chlorinated and has a high pH (>8), often occurring with the use of chloramines as a disinfectant. It is advisable to remove any oxidant (chlorine, chloramine, or peroxide) before the anion unit.

- As water passes through a chloride-form anion resin, alkalinity is removed, leading to a decrease in pH. The anion resin has a limited capacity for alkalinity, causing a brief pH decrease during the service cycle. The treated water's chloride content increases, and it is essential to check local water treatment regulations for any chloride limits. Chlorides have a secondary drinking water standard of 250 ppm. If influent water TDS levels exceed 800 ppm, a salty taste may be detected in the treated water, necessitating the use of reverse osmosis (RO) to reduce TDS and eliminate the salty taste.

Methods of Cleaning:

- To address calcium carbonate precipitation, a weak acid such as citric or phosphoric acid proves effective. Compatibility with the unit and associated plumbing is essential when selecting a cleaning agent, and this method is generally suitable for treating various types of metal fouling.

- When tannin color passes through a previously functioning unit, an attempt to clean the resin is warranted. For this, soda ash (Na2CO3) can be introduced into the brine to aid in cleaning the anion resin. Typically, 0.5 to 1 pound of soda ash is added to the brine well. The soda ash elevates the pH of the brine, causing the resin to swell further, enlarging the pores for enhanced elution of tannins. Additionally, tannins are more soluble at higher pH levels, creating an environment conducive to stripping them from the resin. Note that this cleaning process may result in the fishy odor. After treating the resin with soda ash, a second regeneration should be conducted to completely convert the resin to the chloride form.

- If soda ash proves ineffective in cleaning the resin, chlorine treatment can be employed as a last resort. Introduce approximately four to eight ounces of standard household bleach into the brine well and initiate the regeneration process. Once a chlorine odor is discernible in the drain line, pause the system for one to two hours, and resume the remainder of the regeneration cycle after the soak. A second regeneration is necessary to eliminate any residual chlorine. It's crucial to recognize that this cleaning procedure is harsh on the resin and should be considered a final option. Oxidants like chlorine can break down ion exchange resin, and although there is no resin on the market that is entirely chlorine-resistant, some are more chlorine-tolerant. The tannin resins in today's water treatment market are relatively chlorine-intolerant. If this treatment proves unsuccessful, replacement should be contemplated.

- If the unit houses both cation and anion, it is advisable to regenerate the bed with salt before attempting any cleaning procedure. Metals, such as iron, may precipitate on the cation resin due to high pH or oxidation.

Alternative Approaches to Tannin Removal:

- Oxidizing agents, such as chlorine, prove effective in breaking down organic compounds like tannins. A simple jar test can reveal the concentration and retention time needed to oxidize tannins. Following the retention tank, an activated carbon unit can eliminate chlorine and potentially adsorb other organic compounds in the water. Certain types of activated carbon alone may also reduce tannin levels to acceptable thresholds. It is crucial to consult with your carbon manufacturer to identify the most suitable product. It's worth noting that the reaction between chlorine and tannins may generate trihalomethanes (THMs), recognized carcinogens.

- Reverse osmosis represents another viable method for tannin removal. Given that tannins are high molecular weight organics, reverse osmosis should effectively reject them. However, tannins may pose a challenge by fouling the membrane in the system. Additionally, installing a whole-house reverse osmosis system to treat all water can be prohibitively expensive. For detailed information, it is recommended to consult with your local water expert.

Conclusion:

- Historically, tannin removal predominantly relied on carbon- and styrene-based ion exchange resins. However, recent advancements in water treatment have introduced acrylic-based and high water retention/low crosslinked styrene-based anion exchange resins to the residential market, demonstrating superior performance in tannin removal compared to traditional ion exchange resins. While no resin achieves 100 percent effectiveness, these newer resins have significantly enhanced success rates. If you haven't attempted tannin treatment recently, it might be worth exploring again. For any new water treatment application or product, conduct pilot testing with several systems in the field. Once the pilot study validates the effectiveness in a specific area, pursue the business.

Storage:

- Proper care is essential for ion exchange resins throughout their storage. Prevent the resins from drying out by regularly inspecting their condition when stored in plastic bags. If the resin is not moist, add sufficient clean demineralized water to maintain a consistently moist state. Store the resin drum in a shaded area, and the recommended storage temperature falls between 20°C and 40°C.

Safety:

- Exercise caution with acid and alkali solutions used for regeneration, as they are corrosive and should be handled to prevent eye and skin contact. When utilizing oxidizing agents, adhere to necessary safety precautions to prevent accidents and potential damage to the resin.

Anion Resin for Tannin Reduction - 5 lbs Bag

A High Capacity Anion Exchange Resin for Domestic Applications

NOTE: Five pounds of resin is enough to refill a 2.5"x 10" refillable filter (for standard 10" housing) about 7 times.

Utilize our potent strong base anion resin to effectively diminish and eliminate tannins from your incoming water supply. Available in bulk bags for convenient refilling of filter cartridges (sold separately). If you're dealing with well water or experiencing persistent brown discoloration that standard sediment or Iron/Manganese filters can't address, consider an anion filter as a potential solution.

Tannins, known for their astringent and bitter taste, are plant polyphenols that bind and precipitate proteins. In the context of water treatment, the term refers to the brown discoloration caused by decaying organic matter, often present in well waters due to the formation of tannins from humic acid. This acid, a complex mixture resulting from the biodegradation of organic matter, contains carboxyl and phenolate groups.

Primary Uses:

- Water purification

- Wastewater treatment

- Biological product processing

- Hydrometallurgy of tungsten

- Molybdenum extraction

Other Applications:

- Water softening

- Desalination of water preparation

- Preparation of pure water and high water

- Amino acid extraction and purification

- Extraction and purification of antibiotics

- Extraction and removal of heavy metal ions

- Separation and purification of rare earth elements

- Organic synthesis reactions, acting as a hydrolysis and acid esterification catalyst.

Tannin Removal

- Addressing tannin removal has posed a challenge for some dealers, with standard strong base macroporous anion resins, crafted from styrene and divinylbenzene, traditionally employed until several years ago. Although effective in certain regions, this resin type encountered limitations in others. Over the past five to ten years, the residential water market has witnessed the introduction of more successful resins, making the tannin removal application more appealing to water treatment dealers.

- Softening the water before the tannin removal unit is often recommended. This step ensures the elimination of hardness and metals like iron, which could potentially compromise the performance of the anion resin. Tannins, however, can pass through softening (cation) resin without adverse effects. When hardness levels exceed 10 grains entering the tannin removal unit, there's a risk of precipitating calcium carbonate, forming a white floc that may impede system flow and obstruct exchange sites on the resin. Additionally, metals like iron can foul the anion resin, diminishing its ability to remove tannins. Methods for cleaning these foulants will be discussed later.

- Tannins, large molecular-weight organic compounds resulting from plant and animal decomposition, primarily exist in surface waters or shallow wells. Two main categories of tannins are Humic acid and Fulvic acid, each exhibiting varying structures depending on the vegetation in a given area. Tannins can impart a yellow to dark tea color to water, affecting taste and odor. While not directly regulated, a secondary drinking water standard of 15 alpha units for color exists, although it is not federally enforced. Although not posing health concerns, tannins are aesthetically displeasing.

- Dealing with tannins in water can be challenging, with treatment methods varying in effectiveness based on location and vegetation. While styrene-based macroporous anion resin has traditionally been used for tannin removal, acrylic-based resins have recently emerged, providing excellent results in most cases. These resins can be manufactured as gels or with macroporosity, and low crosslinked/high water retention styrene-based resins have also proven successful in some applications.

| Property | Specification |

|---|---|

| Applications | Removal of organics and color from water |

| Resin Type | Macroporous Strong Base Anion |

| Matrix Type | Styrene divinylbenzene copolymer |

| Functional Groups | Quaternary ammonium |

| Ionic form as supplied | Chloride |

| Total exchange capacity | 0.95 meq/ml, minimum |

| Moisture holding capacity | 57 - 66 % |

| Uniformity co-efficient | 0.45 to 0.55 mm |

| Effective size | 0.8 |

| Maximum operating temperature | 125℉ |

| Operating pH range | 4 to 10 for organic removal |

| Resistance to reducing agents | Good |

| Resistance to oxidizing agents | Generally good, chlorine should be absent |

| Particle size range : 0.3 to 1.2 mm > 1.2 mm <0.3 mm |

0.3 to 1.2 mm 5.0%, maximum 1.0%, maximum |

If your well water exhibits a slight yellow or brown tint, adding one pound per inch in diameter to your media tank typically restores clarity to the water. For darker water resembling iced tea, you may require up to two pounds per inch in diameter of your media tank.

Although there's mention of using a separate tank solely for tannin removal, our approach involves directly introducing these beads into the existing tank, on top of the regular ones in the water softener, without removing any beads.

To assess the "color" or "tannins," run the water at the well for a brief period, then promptly take a sample in a white cup, bucket, or clear glass. Observe the color immediately before the iron has a chance to react with the air (oxygen). Only if color is present when water is initially drawn would the additional tannin removal resin be deemed necessary alongside your regular softening resins.

Application - Organics; Tannin Removal and Demineralization - Demonstrates excellent resistance to fouling.

Here is some general information on estimating the approximate level of tannins in your water.

| Concentration in parts-per Million (PPM) | Water Color |

|---|---|

| 0.0 - 0.5 | Faint tinge of yellow |

| 0.5 - 2.0 | Darker golden yellow |

| 2.0 - 3.0 | Light team color |

| 3.0 - 5.0 | Dark tea color |

Service Cycle Overview:

- The process of tannin removal using anion exchange resins involves a dual mechanism of ion exchange and absorption. Tannins, possessing a slightly negative charge, are exchanged for chloride ions on the resin. Additionally, it is believed that the anion resin can absorb organic compounds. Regeneration of the anion resin is achieved using salt, typically brined at around 10 lbs per cubic foot of salt (NaCl). Regular regeneration is crucial to maintaining resin efficacy.

- Once tannins are exchanged or absorbed onto the resin, they tend to migrate into the inner matrix of the resin bead. Timely regeneration, ideally every two to three days, is essential. Frequent regenerations decrease the likelihood of organic fouling, while extended intervals promote fouling, regardless of whether the anion resin is acrylic or styrene-based.

- The incorporation of tannin resin with softening resin is a common practice, optimizing equipment space and reducing system costs. However, during regeneration, salt may displace calcium from the cation resin and potentially alkalinity from the anion/tannin resin, leading to calcium carbonate precipitation. Indicators of precipitation include a white precipitate in the resin bed, a coating on the drain line, a pressure drop through the system, or a milky-white substance in the backwash water. Cleaning methods will be discussed later.

- Anion resin, with lower density compared to cation resin, requires a distinct backwash flow rate. While the backwash flow rate for cation-softening resin is approximately five gpm/square foot (sf) of area, the anion should be backwashed at around two gpm/sf. In dual bed systems combining softening and tannin removal resins, backwash adjustments or the use of an upper screen or basket in the valve prevent resin loss.

- Tannin resin is often associated with a fishy odor, attributed to the release of an amine by-product from the anion resin. Although the amine concentrations are generally low, the odor threshold is around 40 parts per billion, causing aesthetic displeasure. The fishy odor is more prevalent when water is chlorinated and has a high pH (>8), often occurring with the use of chloramines as a disinfectant. It is advisable to remove any oxidant (chlorine, chloramine, or peroxide) before the anion unit.

- As water passes through a chloride-form anion resin, alkalinity is removed, leading to a decrease in pH. The anion resin has a limited capacity for alkalinity, causing a brief pH decrease during the service cycle. The treated water's chloride content increases, and it is essential to check local water treatment regulations for any chloride limits. Chlorides have a secondary drinking water standard of 250 ppm. If influent water TDS levels exceed 800 ppm, a salty taste may be detected in the treated water, necessitating the use of reverse osmosis (RO) to reduce TDS and eliminate the salty taste.

Methods of Cleaning:

- To address calcium carbonate precipitation, a weak acid such as citric or phosphoric acid proves effective. Compatibility with the unit and associated plumbing is essential when selecting a cleaning agent, and this method is generally suitable for treating various types of metal fouling.

- When tannin color passes through a previously functioning unit, an attempt to clean the resin is warranted. For this, soda ash (Na2CO3) can be introduced into the brine to aid in cleaning the anion resin. Typically, 0.5 to 1 pound of soda ash is added to the brine well. The soda ash elevates the pH of the brine, causing the resin to swell further, enlarging the pores for enhanced elution of tannins. Additionally, tannins are more soluble at higher pH levels, creating an environment conducive to stripping them from the resin. Note that this cleaning process may result in the fishy odor. After treating the resin with soda ash, a second regeneration should be conducted to completely convert the resin to the chloride form.

- If soda ash proves ineffective in cleaning the resin, chlorine treatment can be employed as a last resort. Introduce approximately four to eight ounces of standard household bleach into the brine well and initiate the regeneration process. Once a chlorine odor is discernible in the drain line, pause the system for one to two hours, and resume the remainder of the regeneration cycle after the soak. A second regeneration is necessary to eliminate any residual chlorine. It's crucial to recognize that this cleaning procedure is harsh on the resin and should be considered a final option. Oxidants like chlorine can break down ion exchange resin, and although there is no resin on the market that is entirely chlorine-resistant, some are more chlorine-tolerant. The tannin resins in today's water treatment market are relatively chlorine-intolerant. If this treatment proves unsuccessful, replacement should be contemplated.

- If the unit houses both cation and anion, it is advisable to regenerate the bed with salt before attempting any cleaning procedure. Metals, such as iron, may precipitate on the cation resin due to high pH or oxidation.

Alternative Approaches to Tannin Removal:

- Oxidizing agents, such as chlorine, prove effective in breaking down organic compounds like tannins. A simple jar test can reveal the concentration and retention time needed to oxidize tannins. Following the retention tank, an activated carbon unit can eliminate chlorine and potentially adsorb other organic compounds in the water. Certain types of activated carbon alone may also reduce tannin levels to acceptable thresholds. It is crucial to consult with your carbon manufacturer to identify the most suitable product. It's worth noting that the reaction between chlorine and tannins may generate trihalomethanes (THMs), recognized carcinogens.

- Reverse osmosis represents another viable method for tannin removal. Given that tannins are high molecular weight organics, reverse osmosis should effectively reject them. However, tannins may pose a challenge by fouling the membrane in the system. Additionally, installing a whole-house reverse osmosis system to treat all water can be prohibitively expensive. For detailed information, it is recommended to consult with your local water expert.

Conclusion:

- Historically, tannin removal predominantly relied on carbon- and styrene-based ion exchange resins. However, recent advancements in water treatment have introduced acrylic-based and high water retention/low crosslinked styrene-based anion exchange resins to the residential market, demonstrating superior performance in tannin removal compared to traditional ion exchange resins. While no resin achieves 100 percent effectiveness, these newer resins have significantly enhanced success rates. If you haven't attempted tannin treatment recently, it might be worth exploring again. For any new water treatment application or product, conduct pilot testing with several systems in the field. Once the pilot study validates the effectiveness in a specific area, pursue the business.

Storage:

- Proper care is essential for ion exchange resins throughout their storage. Prevent the resins from drying out by regularly inspecting their condition when stored in plastic bags. If the resin is not moist, add sufficient clean demineralized water to maintain a consistently moist state. Store the resin drum in a shaded area, and the recommended storage temperature falls between 20°C and 40°C.

Safety:

- Exercise caution with acid and alkali solutions used for regeneration, as they are corrosive and should be handled to prevent eye and skin contact. When utilizing oxidizing agents, adhere to necessary safety precautions to prevent accidents and potential damage to the resin.

-

Brand

-

Operating Pressure:

-

Operating Temperature:

-

Flow Rate:

-

Dimensions:

-

Weight:

-

Filter Cartridges Should be Changed:

-

Warranty:

-

Operating Pressure:

-

Operating Temperature:

-

Flow Rate:

-

Dimensions:

-

Weight:

-

Filter Cartridges Should be Changed:

-

Warranty:

-

Operating Pressure:

-

Operating Temperature:

-

Flow Rate:

-

Dimensions:

-

Weight:

-

Filter Cartridges Should be Changed:

-

Warranty:

-

Operating Pressure:

-

Operating Temperature:

-

Flow Rate:

-

Dimensions:

-

Weight:

-

Filter Cartridges Should be Changed:

-

Warranty:

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.