Commercial RO Membrane 2540 (2.5-Inch x 40-Inch)

Commercial RO Membrane 2540 (2.5-Inch x 40-Inch) - ULP 2540 is backordered and will ship as soon as it is back in stock.

Description

Description

Commercial water filtration systems are custom-designed to fulfill the water quality requirements of businesses and industries. Their purpose is to enhance operations and products through the provision of superior water purification.

Adhering to Strict Standards: These systems ensure that the water they produce complies with exacting industry standards for quality and purity, rendering them suitable for diverse applications.

Variety of Membranes:

BW 2540 HF 800 GPD Brackish Water RO Membrane Component: Tailored for use in brackish water contexts, this membrane offers an impressive filtration capacity of 800 gallons per day (GPD). It is designed for treating water with salt concentrations ranging from 2000 to 8000 ppm.

ULP 2540 750 GPD Commercial Reverse Osmosis RO Membrane: Optimized for general commercial reverse osmosis applications, this membrane delivers a capacity of 750 GPD. It effectively treats water with salt concentrations below 1500 ppm.

XLP 2540 600 GPD Commercial Extreme Low-Pressure RO Membrane Component: Particularly suitable for filtering maple sap within the syrup production industry, this membrane is adept at treating water with salt concentrations under 1000 ppm.

SW 2540 500 GPD Sea Water RO Membrane Component: Custom-made for desalination purposes, this membrane is perfect for sea water applications and is deployed in commercial reverse osmosis systems for seawater treatment. It effectively treats water with salt concentrations ranging from 15,000 to 40,000 ppm.

Stainless Steel Housing: This commercial stainless steel 2.5-inch x 40-inch membrane pressure vessel housing operates with a 3/8" water inlet and a 1/4" water outlet.

These membranes use the latest technology and materials to optimize water filtration efficiency.

The membranes are engineered to offer exceptional water purification capabilities, ensuring that water quality attains the highest benchmarks.

The array of membrane options provided covers a spectrum of commercial water treatment scenarios, ranging from brackish water and standard commercial reverse osmosis to low-pressure conditions and seawater desalination. This diversity empowers businesses to select the membrane that best aligns with their specific water filtration needs, ensuring a consistent supply of high-quality water for their operations and products.

Shipping & Returns

Shipping & Returns

Shipping

We currently ship to the United States and Canada. To enquire about shipping to a different destination, please contact us.

Standard shipping normally takes 3-9 days. Next-day shipping is available on all domestic orders (for an additional charge). International shipping times depend on the products and destination (estimated at checkout).

Returns

Items must be returned within 30 days after receiving your order. Items must be returned in the same condition in which they were received, be unworn/unused, have any tags still attached, and include all the original packaging.

Please be aware that the seller will not cover the cost of the return label. It is the customer's responsibility to generate the return shipping label and send the system back to our warehouse.

Refunds

Refunds are processed within 7 days from when we receive the item(s).

Join and get free shipping on orders over $100

First-time purchasers will receive a special discount code sent to their email.

ULP 2540 Commercial RO Membrane

Introducing the ULP-2540 750 GPD Commercial RO Membrane, a highly dependable choice for water filtration in commercial drinking water systems. These Reverse Osmosis membrane elements are renowned for their consistent performance, made possible through advanced membrane technology and automated fabrication. Shipped dry for ease of handling and extended shelf life, our ISO 9001-rated membranes operate at 60 PSI and can purify approximately 20% more water than competing elements at the same pressure.

The ULP 2540 standard flow membrane system is designed to produce 750 gallons per day (GPD) at an operating pressure of 150 PSI. However, if you reduce the incoming city water pressure to a range of 60 to 80 PSI, the reduced pressure will result in a lower permeate flow rate. In this case, you can expect the permeate flow to be approximately in the range of 300 to 400 GPD, depending on the specific incoming low pressure applied. We recommend replacing your membrane every two years.

Key Features:

- Effectively removes particles down to 1/10,000th of a micron, eliminating 98% of impurities, including organics, inorganics, and chemicals.

- Maintains stable, high rejection of contaminants, even with high TDS water sources.

- Utilizes advanced membrane technology with an innovative thin-layer composite membrane design, resulting in more consistent performance and less fouling, necessitating fewer cleanings and replacements.

- Ensures 100% dry storage for an extended shelf life.

General Guidelines:

- Discard the initial permeate from the first full tank, avoiding its use for drinking water or food preparation as it may contain carbon fines and manufacturing by-products.

- Keep the membrane moist at all times after initial wetting.

- For extended system shutdowns, it's recommended to immerse membrane elements in a preservative solution to prevent biological growth.

- While the membrane resists short-term contact with chlorine (hypochlorite), prolonged exposure should be avoided to prevent damage.

- Strict adherence to the operating limits and guidelines outlined in this bulletin is essential to maintain the limited warranty.

The ULP-2540 membrane is an ideal choice for commercial reverse osmosis systems, providing top-tier filtration and reliable performance for a range of applications. They fit standard 2.5" x 40" membrane housings, whether stainless steel, PVC, or fiberglass.

Applications:

This membrane is suitable for residential reverse osmosis systems, schools and educational institutions, commercial establishments, such as restaurants, coffee shops, small-scale food processing facilities, office buildings, hospitals and healthcare, ice machines, public water dispensers, manufacturing and processing, recreational facilities, and more.

| Technical Parameters | Values |

|---|---|

| Stable Rejection Rate | 99.35% |

| Maximum TDS | Below 1500 PPM |

| Production Rate | 750 GPD @150 PSI |

| Max Feed Water Flow | 1.4 m3/h |

| Free Chlorine Concentration of FeedWater | 0.1 mg/l |

| pH Range of Feed Water During Continuous Operation | 3-10 |

| pH Range of Feed Water During Chemical Cleaning | 1-13 |

| Max. Pressure Drop of Single Membrane Element | 10 PSI(0.07 Mpa) |

| Change Membrane | Every 2 Years |

| Testing Certification | ISO 9001 |

XLP 2540 Commercial RO Membrane

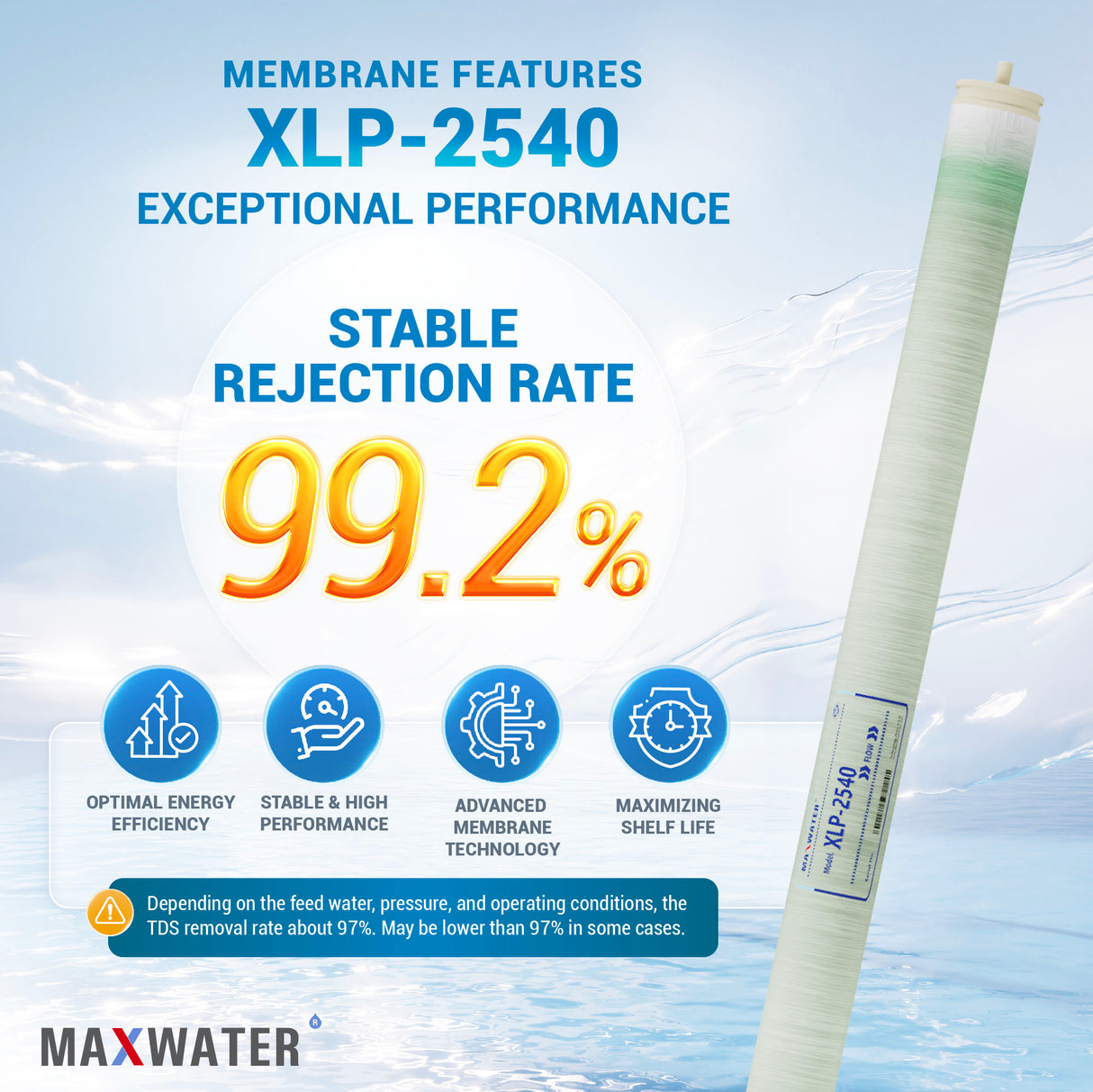

Introducing the Max Water XLP-2540 600 GPD Commercial RO Membrane, a specialized solution tailored for maple sap filtration.

Best for Maple Sap Filtration:

Our XLP-2540 membrane is your ideal choice for filtering maple sap, allowing for a greater flow while effectively screening out impurities. As concentration increases, it can pass small amounts of sugar.

For more in-depth guidance, check our PDF file A Sap to Syrup Guide.

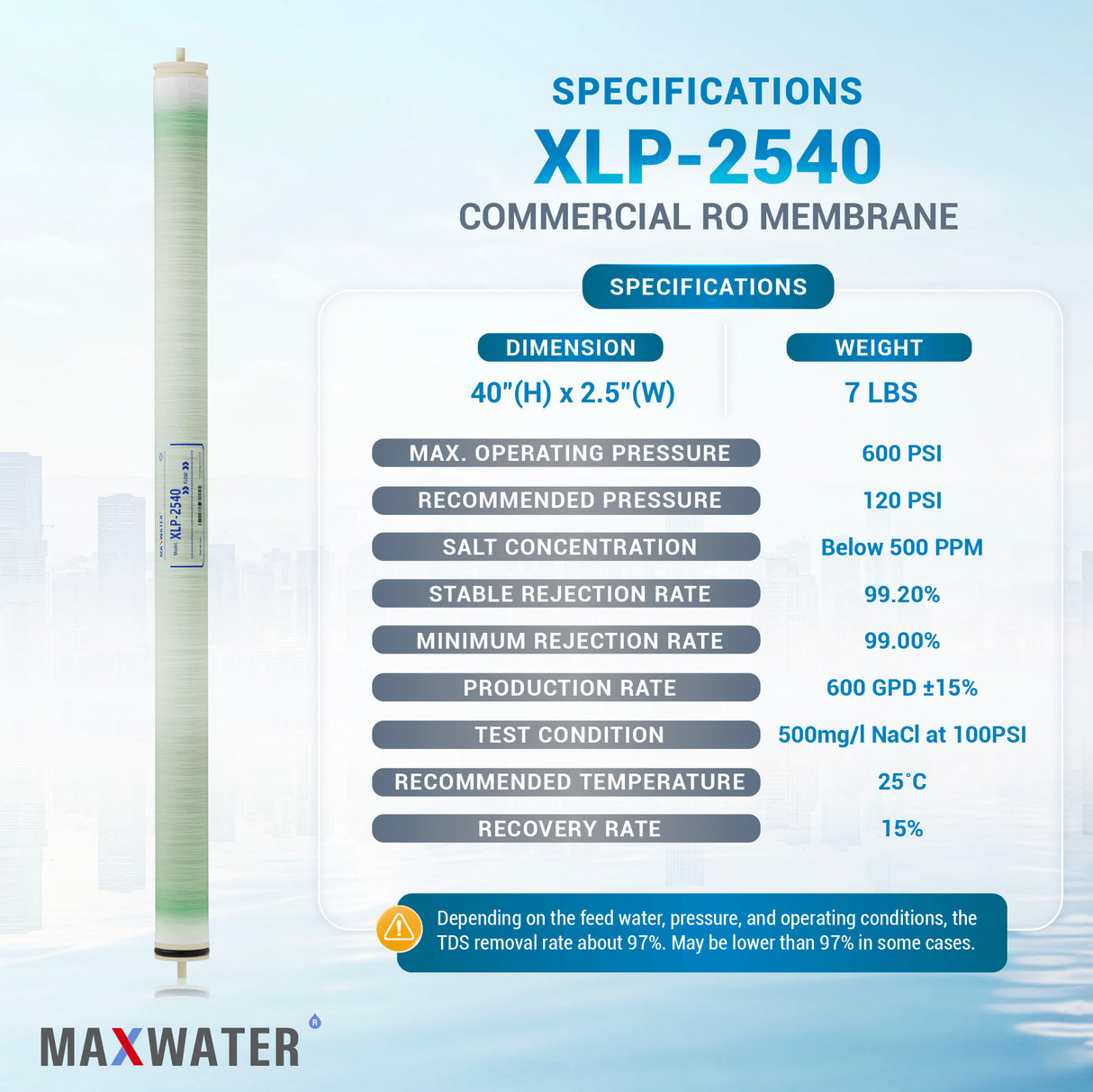

The XLP 2540 membrane is designed to produce 600 gallons per day (GPD) at an operating pressure of 100 PSI. However, if you reduce the incoming city water pressure to a range of 60 to 80 PSI, the reduced pressure will result in a lower permeate flow rate. In this case, you can expect the permeate flow to be approximately in the range of 360 to 480 GPD, depending on the specific incoming low pressure applied. We recommend replacing your membrane every two years.

Key Specifications:

- 600 Gallon Per Day Membrane certified to ISO 9001 standards.

- Removes particles down to 1/10,000th of a micron, eliminating 98% of impurities including organics and inorganics.

Performance Highlights:

- Ensures stable, high rejection of impurities, even with high TDS water sources.

- Employs advanced membrane technology with an innovative thin-layer composite membrane design.

- Maintains more consistent performance with less fouling, requiring less frequent cleaning and change-outs.

- Stored 100% dry, maximizing its shelf life.

Guidance and Tips:

- Discard the initial permeate from the first full tank, avoiding its use for drinking water or food preparation, as it may contain carbon fines and manufacturing by-products.

- Keep the membrane moist after initial wetting.

- For extended system shutdowns, it's recommended to immerse the membrane elements in a preservative solution to prevent biological growth.

- While the membrane resists short-term contact with chlorine (hypochlorite), prolonged exposure should be avoided to prevent damage.

- Strictly adhere to the operating limits and guidelines outlined in this bulletin to maintain the limited warranty.

Versatile Applications:

The XLP-2540 RO Membrane is compatible with various applications, including maple sap filtration, car washes, whole-house RO systems, commercial RO, agricultural, and industrial uses. Commonly referred to as Extra Low Pressure, Extra Low Energy, Ultra Low Pressure, or Ultra Low Energy, it fits nearly all standard 2.5" x 40" membrane housings, whether stainless steel, PVC, or fiberglass.

The XLP-2540 membrane is your trusted choice for superior maple sap filtration, offering high performance, consistent results, and versatility across a range of applications.

| Technical Parameters | Values |

|---|---|

| Stable Rejection Rate | 99.20% |

| Maximum TDS | Below 500 PPM |

| Production Rate | 600 GPD @100 PSI |

| Max Feed Water Flow | 1.4 m3/h |

| Free Chlorine Concentration of FeedWater | 0.1 mg/l |

| pH Range of Feed Water During Continuous Operation | 3-10 |

| pH Range of Feed Water During Chemical Cleaning | 1-13 |

| Max. Pressure Drop of Single Membrane Element | 10 PSI(0.07 Mpa) |

| Change Membrane | Every 2 Years |

| Testing Certification | ISO 9001 |

BW 2540 Commercial RO Membrane

Introducing the Max Water BW 2540 800 GPD Commercial RO Membrane, which excels in providing dependable water filtration for various applications. These Reverse Osmosis membrane elements are celebrated for their unwavering performance, backed by advanced membrane technology and automated fabrication. We ship these membranes dry for easy handling and extended shelf-life, and they are certified to ISO 9001 standards.

The BW-2540 standard flow membrane system is designed to produce 800 gallons per day (GPD) at an operating pressure of 225 pounds per square inch (PSI). However, if you reduce the incoming city water pressure to a range of 80 to 100 PSI, the reduced pressure will result in a lower permeate flow rate. In this case, you can expect the permeate flow to be approximately in the range of 285 to 355 GPD, depending on the specific incoming low pressure applied. We recommend replacing your membrane every two years.

Key Features:

- Efficiently removes particles down to 1/10,000th of a micron, eliminating 98% of impurities, including organics, inorganics, and chemicals.

- Ensures stable, high rejection of contaminants, even with high TDS water sources.

- Utilizes advanced membrane technology with an innovative thin-layer composite design, resulting in more consistent performance and less frequent cleaning and changeouts.

- Maintains 100% dry storage, maximizing shelf life.

General Guidelines:

- Discard the initial permeate from the first full tank as it may contain carbon fines and manufacturing by-products.

- Keep the membrane moist after initial wetting.

- During prolonged system shutdowns, immerse the membrane elements in a preservative solution to prevent biological growth.

- While the membrane resists short-term contact with chlorine (hypochlorite), continuous exposure should be avoided to prevent damage.

- Adherence to operating limits and guidelines is crucial to maintain the limited warranty.

Applications:

This membrane is suitable for desalinating surface water, groundwater, and treating water with salt concentrations between 2000 and 8000 ppm. It finds versatile use in medicine, the chemical industry, beverage production, electricity generation, and more.

Max Water BW-2540 RO Membranes are versatile, catering to a wide array of applications, including car washes, whole house RO systems, commercial RO, agricultural, and industrial uses. They fit standard 2.5" x 40" membrane housings, whether stainless steel, PVC, or fiberglass.

| Technical Parameters | Values |

|---|---|

| Stable Rejection Rate | 99.60% |

| Maximum TDS | 2000 - 8000 PPM |

| Production Rate | 800 GPD @225 PSI |

| Max Feed Water Flow | 1.4 m3/h |

| Free Chlorine Concentration of FeedWater | 0.1 mg/l |

| pH Range of Feed Water During Continuous Operation | 3-10 |

| pH Range of Feed Water During Chemical Cleaning | 1-13 |

| Max. Pressure Drop of Single Membrane Element | 10 PSI(0.1 Mpa) |

| Change Membrane | Every 2 Years |

| Testing Certification | ISO 9001 |

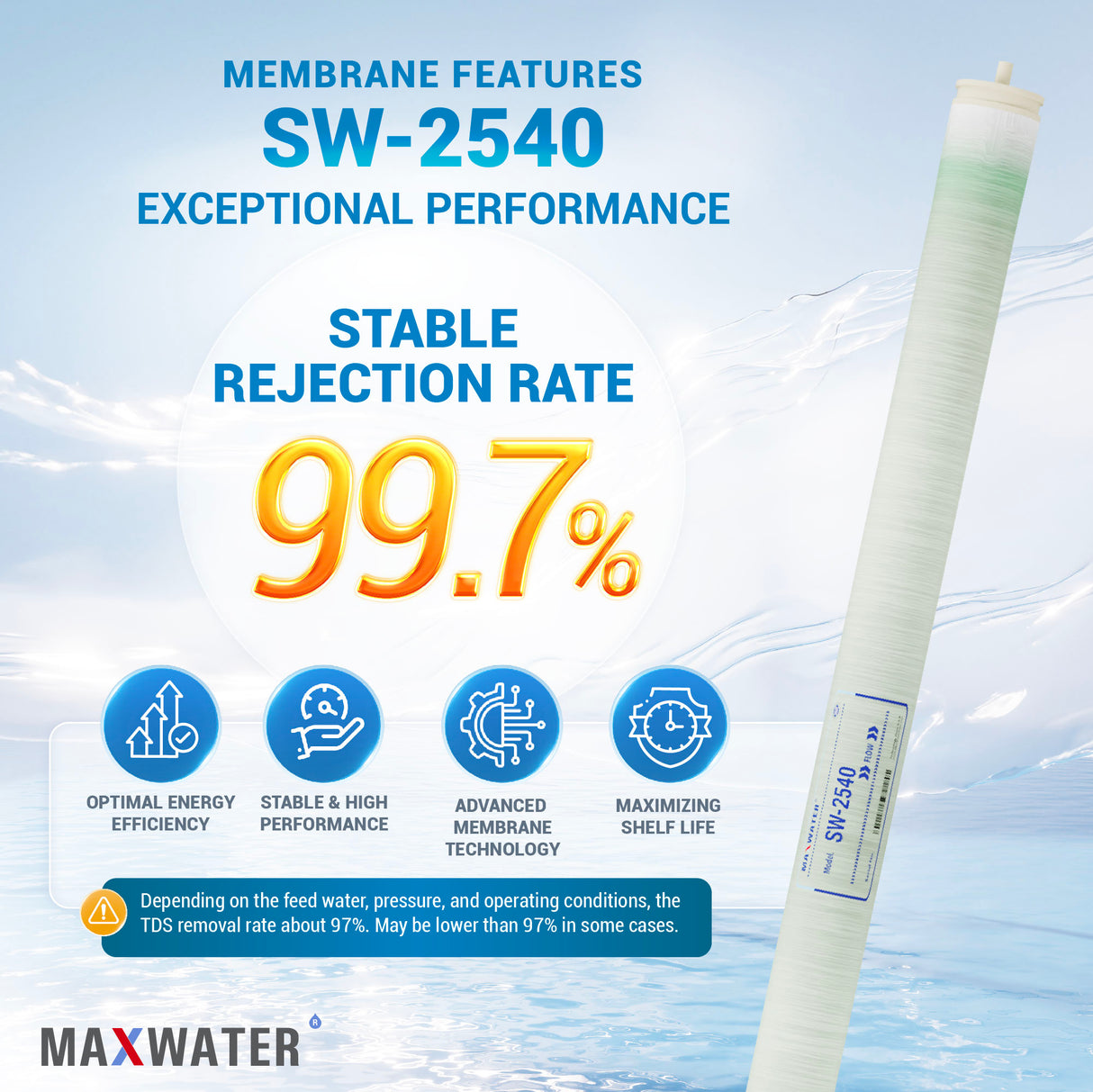

SW 2540 Commercial RO Membrane

Max Water SW 2540 750 GPD Commercial RO Membrane - an optimal choice for sea and brackish water treatment applications.

Key Features:

- High Salt Rejection: Specifically designed for seawater and brackish water treatment, this membrane offers high salt rejection, ensuring clean and safe water for various applications such as industrial, pharmaceutical, boiler replenishment, food processing, agricultural use, and whole-house water purification.

- Efficient Filtration: With a maximum capacity of 750 gallons per day (GPD) and an average permeate flow of 600 GPD, this 2.5" inch by 40" inch reverse osmosis membrane employs advanced technology for efficient filtration. It effectively removes impurities and contaminants, delivering clean, clear, and fresh-tasting water.

Reliable RO Technology:

Reverse Osmosis membrane elements are recognized as the most reliable method for water filtration in commercial systems. Their consistency and performance are backed by advanced membrane technology and automated fabrication, instilling trust in equipment suppliers, water filtration dealers, and residential customers. These membranes are shipped dry for easy handling and prolonged shelf life.

Maintenance Guidelines:

For optimal performance, we recommend replacing your membrane every two years. The initial tank of permeate should be discarded to avoid using it for drinking or food preparation, as it may contain carbon fines and manufacturing by-products. Keep the membrane moist after initial wetting. In cases of prolonged system shutdowns, immerse the membrane elements in a preservative solution to prevent biological growth.

Versatile Applications:

This Max Water SW 2540 Reverse Osmosis Membrane is versatile and suited for a range of applications, including industrial use, pharmaceutical processes, food and beverage production, agricultural needs, and comprehensive whole-house water purification. Its adaptability makes it an ideal choice for businesses and households seeking a reliable, cost-effective solution for their water treatment requirements. It fits nearly all standard 2.5" x 40" membrane housings, whether stainless steel, PVC, or fiberglass.

Durability and Longevity:

Constructed with high-quality materials and advanced manufacturing processes, the Max Water SW 2540 RO Membrane is built to last. Its robust design ensures durability and reliability, consistently providing high-quality water treatment for years to come.

In summary, the Max Water SW 2540 750 GPD Commercial RO Membrane is a reliable and efficient solution for sea and brackish water treatment, offering high salt rejection, versatile applications, and long-lasting performance for various water treatment needs.

| Technical Parameters | Values |

|---|---|

| Stable Rejection Rate | 99.70% |

| Maximum TDS | 15000 - 40000 PPM |

| Production Rate | 750 GPD @800 PSI |

| Max Feed Water Flow | 1.4 m3/h |

| Free Chlorine Concentration of FeedWater | 0.1 mg/l |

| pH Range of Feed Water During Continuous Operation | 3-10 |

| pH Range of Feed Water During Chemical Cleaning | 1-13 |

| Max. Pressure Drop of Single Membrane Element | 15 PSI(0.1 Mpa) |

| Change Membrane | Every 2 Years |

| Testing Certification | ISO 9001 |

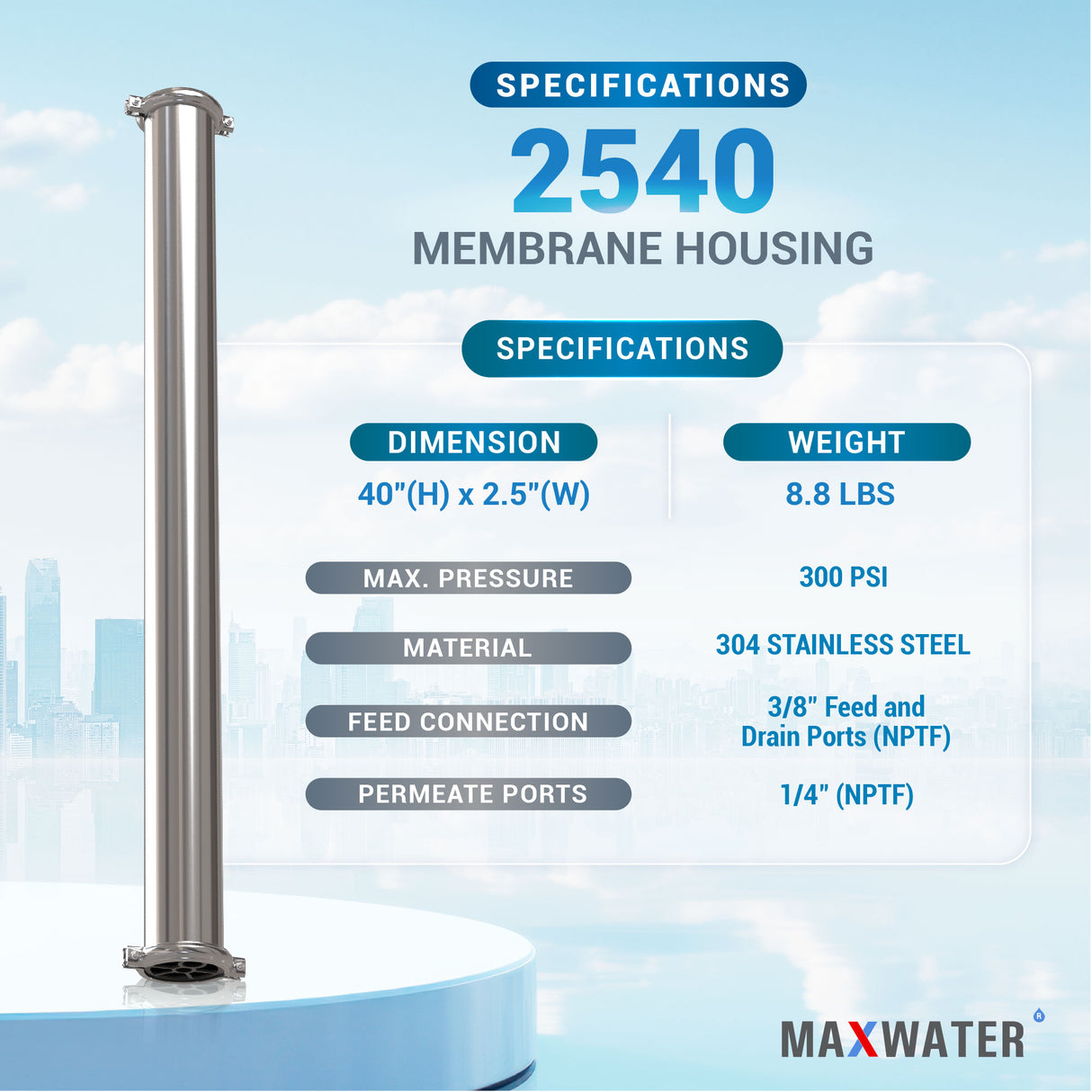

2540 Membrane Housing

Max Water Heavy-Duty 2540 Membrane Housing - a robust solution designed for industrial use.

Key Features:

- Industrial-Grade Design: This commercial stainless steel 2.5" x 40" Membrane Pressure Vessel Housing is built to meet the demands of industrial applications, ensuring reliability and durability.

Housing Specifications:

- Max Working Pressure: With a maximum working pressure of 300 PSI, this housing can withstand high pressures in various industrial settings.

- Feed/Concentrate and Permeate Ports: Equipped with 3/8" Feed and Drain Ports (NPTF) for efficient water flow management and 1/4" Permeate Ports (NPTF) for collecting the purified water.

- Stainless Steel Construction: Made from type 304 stainless steel, this housing is known for its corrosion resistance, making it suitable for industrial environments.

- Secure End Port Caps: The housing comes with double O-ring end port caps to ensure a secure and leak-free fit.

- Complete Kit: Stainless clamps and stainless hardware, along with brackets, are included, providing you with a comprehensive solution for your membrane housing needs.

In summary, the Max Water Heavy-Duty 2540 Membrane Housing is a reliable and robust choice for industrial applications, featuring a high-pressure rating, stainless steel construction, and all the necessary components for secure and efficient water filtration.

-

Brand

-

Operating Pressure:

-

Recommended Pressure:

-

Maximum TDS:

-

Operating Temperature:

-

Production Rate:

-

Dimensions:

-

Weight:

-

Filter Cartridges Should be Changed:

-

Warranty:

-

Operating Pressure:

-

Recommended Pressure:

-

Maximum TDS:

-

Operating Temperature:

-

Production Rate:

-

Dimensions:

-

Weight:

-

Filter Cartridges Should be Changed:

-

Warranty:

-

Operating Pressure:

-

Recommended Pressure:

-

Maximum TDS:

-

Operating Temperature:

-

Production Rate:

-

Dimensions:

-

Weight:

-

Filter Cartridges Should be Changed:

-

Warranty:

-

Operating Pressure:

-

Recommended Pressure:

-

Maximum TDS:

-

Operating Temperature:

-

Production Rate:

-

Dimensions:

-

Weight:

-

Filter Cartridges Should be Changed:

-

Warranty:

-

Operating Pressure:

-

Dimensions:

-

Weight:

-

Warranty:

2.5" x 40" Membrane

Installation Video

2.5" x 40" Membrane

Installation Video

2.5" x 40" Membrane

Installation Video

2.5" x 40" Membrane

Installation Video

2.5" x 40" Housing

Housing End Caps

Housing Fasteners

Housing Mounting Arms

Housing Cushions

O-Rings

Screws

Installation Video

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.